For the development of manufacturing escort LOCTITE glue instant dry adhesive series new launch

In the world's nearly 300 years of industrialization, manufacturing industry has an indispensable and important position. In recent years, the rapid development of the manufacturing industry is not without the support of every related company, and LOCTITE is one of the leaders in the global adhesive market. As the leading brand in the industrial glue industry, LOCTITE is committed to ensuring the safety and productivity of the manufacturing industry.

LOCTITE continues to achieve leadership through innovation

Development requires innovation, and LOCTITE, a leader in the industrial glue industry, understands this. Throughout the history of LOCTITE, it is a history of struggle to lead the development of the industry with innovation across the long river of time.

Bolts and nuts are easy to loosen, which used to be a common pain point and problem in the machinery industry. Until 1953, a doctor named Vernon Krieble developed a new bonding material in the United States laboratory, anaerobic curing agent (later named LOCTITE). As a unique adhesive resin that cures in the absence of air, LOCTITE glue allows loose bolts and nuts to be tightly bonded, solving a problem that has plagued the mechanical industry for more than 100 years.

LOCTITE, which has created a blockbuster in industrial production, is not complacent. On the contrary, it has accelerated the pace of innovation, constantly developing new products for different industrial scenarios. From the 1950s to the present, LOCTITE has a wide range of adhesives including quick-drying adhesives, thread locking adhesives, thread sealants, flat sealants, cylindrical holding adhesives, as well as a wide range of complementary products such as cleaning agents, activators, automatic/semi-automatic dispensing equipment and wear resistant coatings. Today, LOCTITE holds a leading position in the industrial glue industry, and its glue products are widely used in electronics, automotive, aerospace and biomedical fields.

To ensure industrial production safety, LOCTITE new upgraded instant dry adhesive series

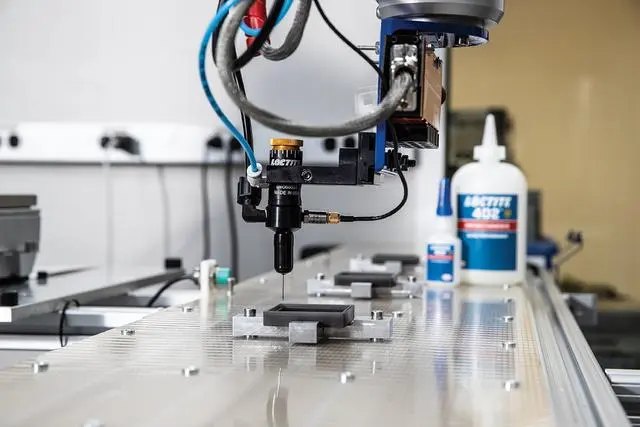

LOCTITE is both safe and uncompromising in performance. In the case of the new LOCTITE 402, slow curing of adhesives, complex and expensive fastening methods, and inefficient manual assembly processes have been the core problems hindering manufacturing efficiency. As a rapidly curing adhesive, LOCTITE 402 plays an important role in preventing premature equipment failure, ensuring long equipment life and reducing warranty claims.

Compared to conventional adhesives, LOCTITE 402 can withstand heat aging up to 275°F/135°C and maintain superior product performance in extreme temperatures. At the same time, LOCTITE 402 can play a high-strength bonding role for metal, rubber, plastic and other difficult bonding substrates, from simple maintenance to high-speed assembly of small parts, it can help improve production efficiency.

In addition, the newly upgraded LOCTITE line of quick-drying adhesives also plays an important role in the manufacturing industry based on different substrates and use scenarios: LOCTITE 401 for high shear on a variety of materials, LOCTITE 406 for bonding small gaps and tightly assembled components, LOCTITE 454 for porous and vertical surfaces, LOCTITE 495 for fast bonding on a variety of materials... Innovative formulations and performance highlight the power and reliability of LOCTITE products. In the future, LOCTITE will continue to make an important contribution to ensuring manufacturing productivity.

From the advent of anaerobic technology, to the widespread use of LOCTITE products in machines and components in various fields, to the important role that LOCTITE glue plays in improving manufacturing efficiency today, LOCTITE has always followed industry developments and market trends to create solutions for assembly processes and equipment maintenance. Today, under the rapid changes of Industry 4.0, LOCTITE glue will continue to provide full support and guarantee with innovative spirit and professional bonding solutions, making an important contribution to the development of the manufacturing industry.

LOCTITE has more than 650 sales engineers covering more than 800 industries, more than 10,000 sales partners, and provides free technical expertise to more than hundreds of thousands of customers in industrial manufacturing, electronics, aerospace, biomedicine and other fields.