MEMS packaging adhesive solution

As a new technology hotspot after microelectronics technology, MEMS(Micro Electromechanical System) provides the interface between the information digital world and the real (analog) world by means of electromechanical systems with a feature scale of micrometers. It provides a new technology platform and research method for the development of science and technology in information, biology, chemistry, machinery and other fields.

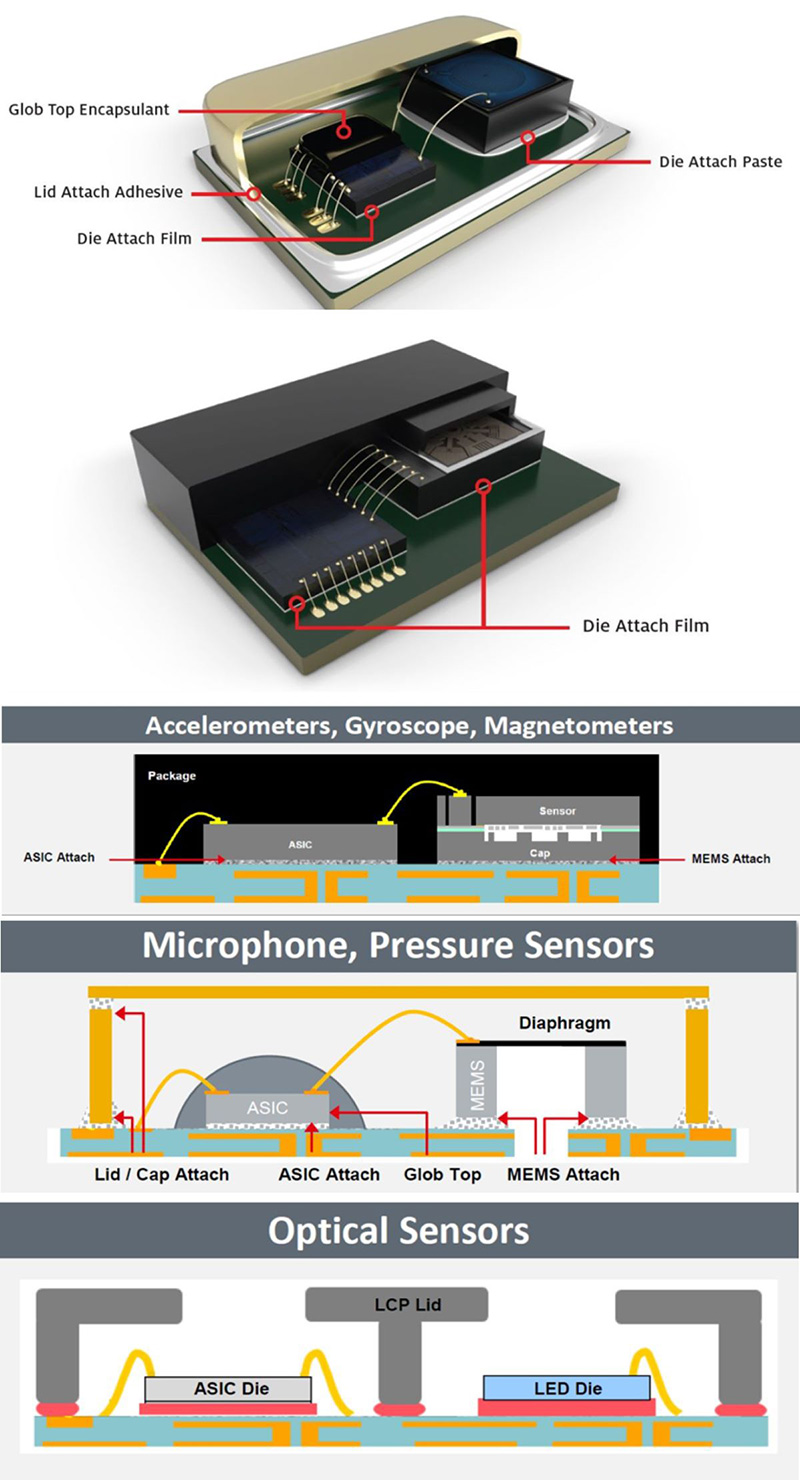

MEMS has been widely used in MEMS accelerometers, MEMS microphones, micro-motors, micro-pumps, micro-oscillators, MEMS pressure sensors, MEMS gyroscopes, MEMS humidity sensors, and their integrated products.

MEMS packaging is difficult, and the current packaging technology is mostly developed and evolved from the continuation of integrated circuit technology, and the requirements for structural assembly bonding, conductive bonding, and sealing bonding partly draw on the standards and requirements of integrated circuit packaging technology. Stable and high-performance bonding solutions provide a strong guarantee for the development and production of high-performance MEMS products.

The application points of MEMS packaging adhesive (adhesive) are mainly several specific application points:

(1) Die Attach Adhesive for MEMS package chip:

Insulating glue, insulating film, conductive silver glue, conductive film can be selected according to the specific function.

Adhesives with high thermal conductivity can be used for bonding high-power chips with high thermal conductivity and heat dissipation requirements.

For stress-sensitive chip bonding, low hardness and low modulus bonding glue can be selected.

For volatile sensitive applications, specially treated adhesives with low outgassing are available;

(2) Lid or Cap Attach Adhesive:

Insulating glue, insulating film, conductive silver glue, conductive film and Bstage glue can be selected according to the specific function of MEMES.

For different cover substrates of MEMS packaging, such as ceramics, LCP, PA, PBT, gold plating, Kovar and other special difficult materials, special adhesives can be used to bond.

For MEMS structure near airtight packaging, Bstage special process glue can be used for packaging.

For the working environment application of MEMS packaging with high temperature resistance, high-temperature glue can be selected for bonding.

(3) MEMS chip encapsulation, coating adhesive (Glob Top, COB, Dam&Fill) :

According to the degree of protection, the working environment can choose different types of encapsulation materials internal sensitive devices for protection.

For stress sensitive applications, you can choose very low CTE, very low shrinkage, high Tg glue for packaging, or choose modulus and hardness glue to protect sensitive chips.

For chips with harsh working environment, such as corrosive gases, liquids, dust, etc., glue package protection with strong resistance to media can be selected.

For chips applied in high temperature environment, high-temperature glue can be used to package protection.

(4) Flip chip Underfill:

Different levels of bottom filler can be selected according to different chip package forms and working conditions such as CSP, FLIP,BGA to increase the reliability of the chip. The appropriate Underfill process can effectively reduce the CTE mismatch between the chip and the substrate, and increase the anti-shock and anti-vibration performance.

For different reliability, you can choose different application levels of automotive electronics, avionics, consumer electronics Underfill glue.

Select repairable and non-repairable Underfill glue based on whether repair is required.

According to the different state of the bottom filling material, different forms of NCP, NCF, CUF can be used to Underfill the bottom filling glue.