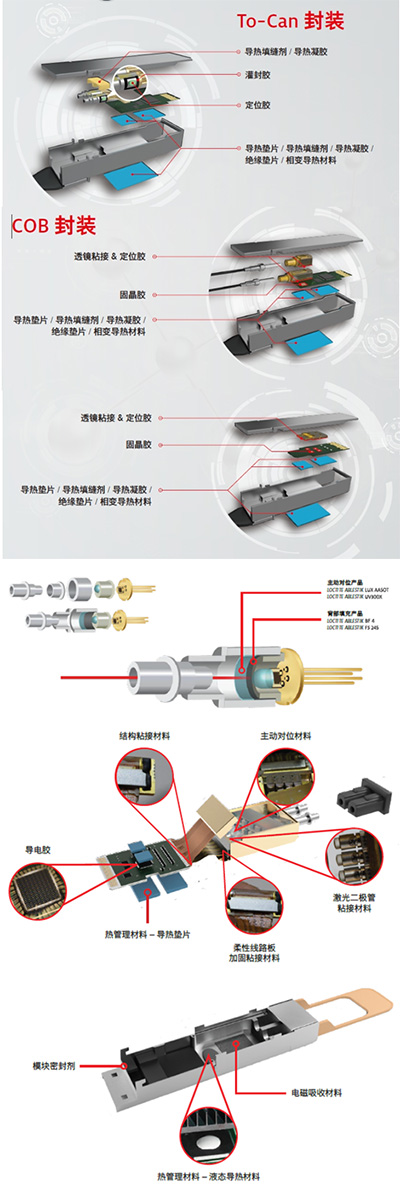

Optical communication bonding, thermal adhesive solutions

Optical communication devices are divided into passive devices and active devices, and different devices have different requirements for adhesive products.

Passive device classification: optical coupler, optical isolator, optical attenuator, optical fiber connector, wavelength division multiplexer/demultiplexer, optical switch.

Active device classification: fiber amplifier, fiber laser, optical detector, optical repeater and optical modulator, etc.

According to different device bonding requirements, adhesives of different materials (acrylic glue, epoxy resin glue, organic silicone, etc.) can be selected to achieve the performance requirements of bonding, sealing, thermal conductivity, and electrical conductivity; Also according to the device itself characteristics, production efficiency and other process requirements, you can choose different curing forms (UV light curing adhesive, room temperature curing adhesive, heating curing adhesive, UV light curing + heating curing adhesive, etc.) to choose different adhesive products.

The basic application of adhesives in optical device products can be divided into: bonding and fixing of pigtail, bonding of filter, bonding of light lens, positioning and bonding of optical device, conductive bonding of chip, sealing and shielding of module shell, and potting protection of device.